|

liton machinery manufacturing co.,ltd

|

Finger Joint

| Place of Origin: | , China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Comb tenoning and splicing is an effective way to connect the timbers to a longer length, is able to increase the utility rate of shorter timbers.

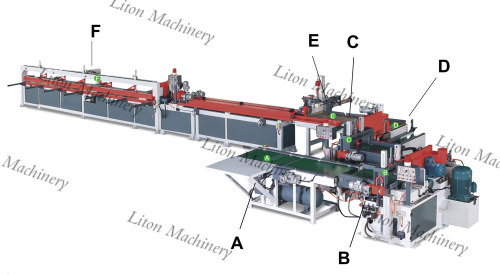

A- MF756/strap conveyor;

*Guide rail of finger joint shaper's conveyor is japan precision linear guide rail to guarantee the shaping accuracy.

*The design for finger joint shaper is doudle blades+tooth-tenon knife assembly to provide high precision.

*The conveyor table of finger joint shaper adopts German pneumatic hydraulic convertor system to control back and forth, smoothly, low maintenance, high quality.

*Reverse material part adopts combination of high quality German pneumatic hydraulic convertor system and decelerating system.

*Feeding for finger joint assembler adopts swivel encoder to count feeding length, and can set length at 2000-6200mm at random by high precision.

*The second push part of finger joint assembler adopts long+short double pushing board design, by this kind of structure, it can assemble very short workpiece to reduce the cost.

B- MXZ3515-Z/ auto finger shaper;

C- MXZ3515T-Z()/ Auto finger shaper(glue-spreading);

D- MF746/roller conveyor;

E- MF761/chain conveyor;

F- MHZ1560/ Auto finger joint assembler*Guide rail of finger joint shaper's conveyor is japan precision linear guide rail to guarantee the shaping accuracy.

*The design for finger joint shaper is doudle blades+tooth-tenon knife assembly to provide high precision.

*The conveyor table of finger joint shaper adopts German pneumatic hydraulic convertor system to control back and forth, smoothly, low maintenance, high quality.

*Reverse material part adopts combination of high quality German pneumatic hydraulic convertor system and decelerating system.

*Feeding for finger joint assembler adopts swivel encoder to count feeding length, and can set length at 2000-6200mm at random by high precision.

*The second push part of finger joint assembler adopts long+short double pushing board design, by this kind of structure, it can assemble very short workpiece to reduce the cost.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Finger Joint Board

Finger Joint Panel

Finger Joint Veneer

Finger Joint Wood

Joint

Finger Clip

More>>